Our 24??media PDFs

24??media Fundamentals Explained

Table of ContentsSome Known Incorrect Statements About 24??media Indicators on 24??media You Need To KnowUnknown Facts About 24??mediaSee This Report on 24??media

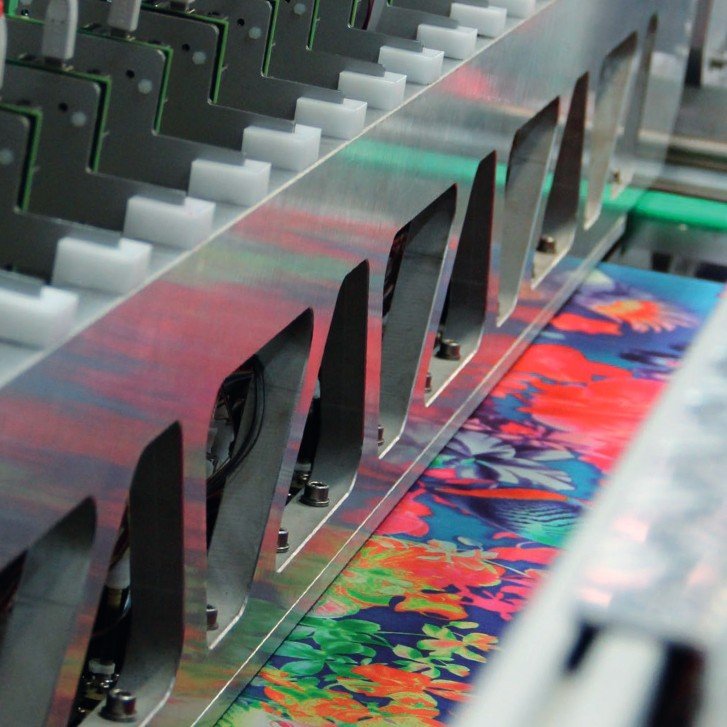

An inkjet printer deposits tiny ink beads onto the paper to create high-grade colour images. Inkjet printers use several advantages, such as: Simplified ease of access Cost-efficiency Increased speed Improved quality One drawback is they have slower printing rates than laser printers. Dry-toner electronic printing, or printer, use printer toner for quickly, durable prints but might not generate the exact same high quality colour pictures as inkjet printers.

Digital offset printing supplies a series of benefits over various other electronic resources, consisting of: Top quality prints Precise shade fidelity Cost-efficiency Ability to generate a large quantity of prints rapidly and effectively However, digital countered printers might be expensive to get and sustain, demanding specialized instruction. We make use of an HP Indigo, which is a digital-offset printer to print all our personalized stickers.

Slim internet printing is related to webs generally 16 inches or much less in width, whereas vast internet printing includes media of a greater width. Normally, narrow web printing is recognized for its focus on photo quality, while wide web printing is renowned for its speed and efficiency. We will certainly take a look at the special applications and advantages of each printing method.

This kind of printing offers higher cost-effectiveness, high-quality result, and the capability to build massive jobs. Wide-format printing commonly consists of inkjet, digital offset, and dry-toner electronic printing alternatives, each with qualities and downsides. Hence, assessing the task's demands prior to picking a printing technique is essential. On the various other hand, narrow web printing is a rotary printing procedure ideal for webs with a width of 16" or much less, making it perfect for printing tags, stickers, and various other small-format items.

What Does 24??media Mean?

Advancements in digital printing technology have actually brought about considerable renovations in print high quality and cost-effectiveness, making it an extra sensible choice for different projects. A lot of the emphasis has actually gotten on the print heads, ink solutions and exactly how to regulate ink diffusion onto the media. Smart methods such as arbitrary dot patterns have actually boosted issues such as banding.

The normal electronic printing equipment has experienced notable development in print high quality, boasting higher resolution, crisper photos, and extra precise colours. As formerly mentioned, this progress is primarily because of growths in the print head, ink and controlling how these communicate with the substrate. Therefore, digital printing provides continuous improvement, precisely reproducing balanced out printing, high-speed and top notch inkjet printing, and a minimised quantity of waste.

Some Of 24??media

With so several options available, it can require time to identify which printer is the best suitable for your demands (Custom Printed Packaging). We will currently provide support on selecting the ideal digital printer to fulfill your particular needs and introduce the leading brands in digital printing. Prior to devoting to a digital printer, carefully examine your specific printing demands and requirements

Discovering the products of these popular digital printer brands and discovering about your certain requirements will certainly lead you to the ideal fit for your projects, guaranteeing top quality print end results. Screen printing is much better for lower comprehensive, bulk orders and is done by hand. On the other hand, electronic printing is more suitable for orders with higher amounts of focused information and is dealt with by a computer.

Litho printing is the far better selection of printing technique if your design calls for a great deal of huge blocks of solid colour, as the colour will come out a whole lot smoother compared to electronic printing. Particularly when making use of a super-sophisticated drying strategy like LED UV, of which B&B was among the initial in the country to mount.

The Only Guide to 24??media

(https://www.gaiaonline.com/profiles/za24media/47032986/)

Litho printing is various as there is a configuration procedure before the printing in fact begins, so there is a configuration charge. This indicates there is an upfront price when it involves litho printing - Small Volume Packaging. You additionally, like the digital printing process, have to spend for the paper and the ink utilized

Litho printing is also quicker than digital printing throughout the print procedure. To create a percentage of material at a low price, electronic printing is the far better choice; however, litho printing image source exercises less costly when it comes to generating a huge amount of print. Brochures, pamphlets, and other advertising and marketing materials can be printed on a range of products such as glossy, silk, uncoated, textured and tinted card or paper.